Welding Software

Xiris Welding Software is purpose-built to deliver real-time and post-process data extraction with extensive configuration options. Specifically designed for welding applications, it offers advanced image processing, machine vision tools, and unique AI-based features. The software combines vision, thermal camera, and audio data, providing enhanced visualization and analysis for superior welding quality and efficiency.

WeldStudio™ 3, WeldStudio™ 3 Pro and WeldSDK

WeldStudio™ 3 is included with purchase of all XVC weld cameras. It includes access to standard tools such as the Recipe Management system for easy and fast set-up and configuration, advance image processing, and the ability to remotely view, record, and playback welding processes.

WeldSudio™ 3 Pro is for advanced users who would benefit from machine vision and thermal measurement tools such as blob segmentation, edge, and thermal temperature reading tools. This version of the software program comes included with purchase of the XIR-1800 thermal camera.

The WeldSDK™ (software development kit) allows advanced Users and OEMs to create custom image processing & display applications for integration into welding machines.

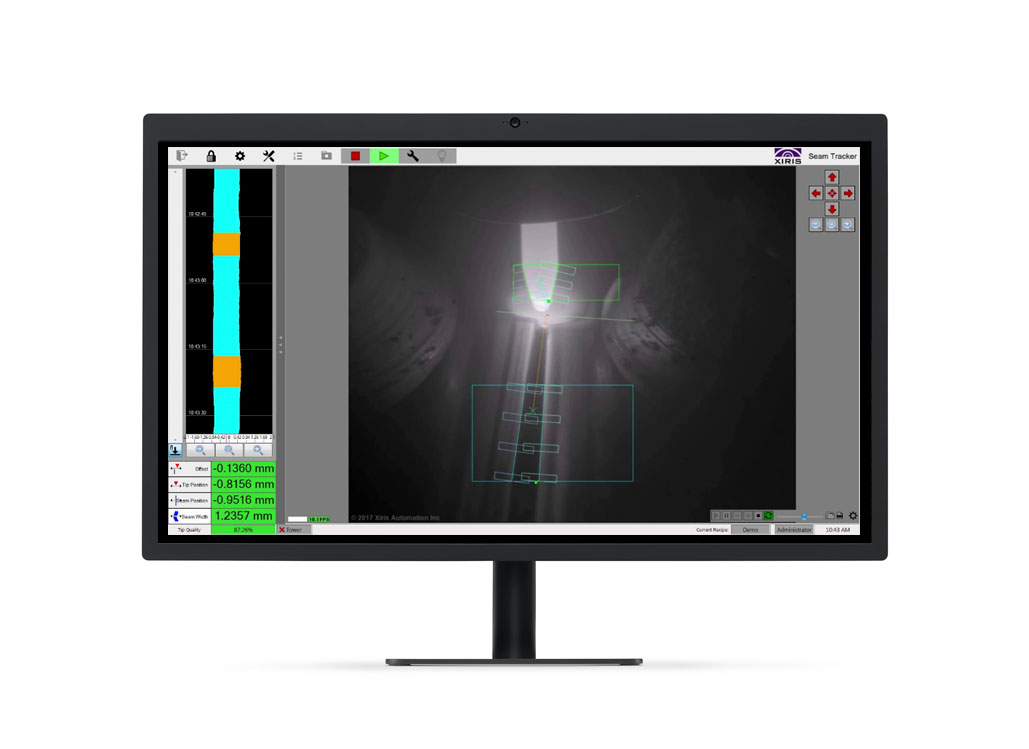

SeamMonitor™

The SeamMonitor™ system measures the alignment of the weld seam relative to the torch tip, the width of the weld seam and the torch tip condition. The system includes a Xiris open arc weld camera system, industrial HMI controller, and SeamMonitor™ software.

- Measures seam width and alignment movement history for process monitoring

- Automatically alerts the operator when out-of-tolerance weld conditions occur

- Integrates with all Xiris High Dynamic Range (HDR) cameras in monochrome or color

- Configurable optics that can be adjusted to suit most common welding environments

- Integrates with other automation hardware and process monitoring systems

Interested in learning more about our weld monitoring cameras?

Join us for a video demo and info session