Weld Monitoring Systems

Welding Automation Powered By Machine Vision + AI

Upgrade your welding and additive manufacturing systems. Smarter monitoring, crystal-clear imaging, real-time data.

AI Vision for the Future of Welding

Get complete visibility into your welding process with advanced machine vision technology. From real-time monitoring to in-depth analysis, our solutions empower your team to make better decisions and optimize quality.

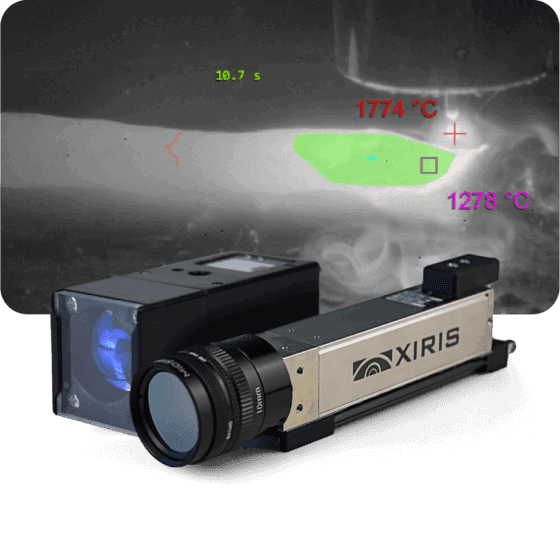

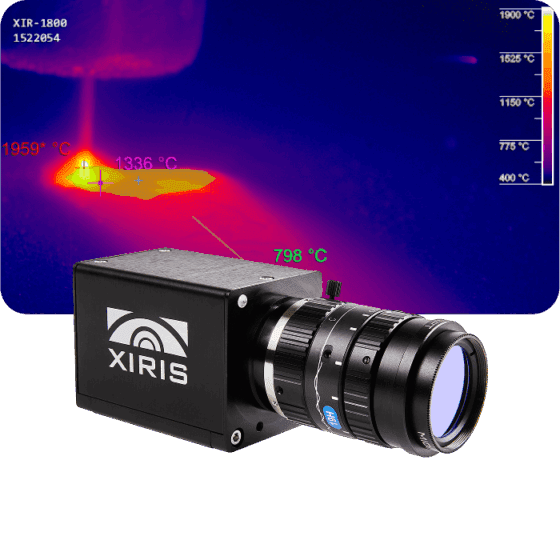

Welding Cameras

Advanced imaging systems designed to capture crystal-clear views of the arc, melt pool, and surrounding areas, even in the darkest welding conditions. Xiris Welding cameras provide the foundation for intelligent weld monitoring.

Tube and Pipe Weld Inspection

Simplify mill setup and reduce downtime with real-time process feedback. Our inspection systems give operators the data they need to make immediate adjustments and maintain consistent quality across every tube.

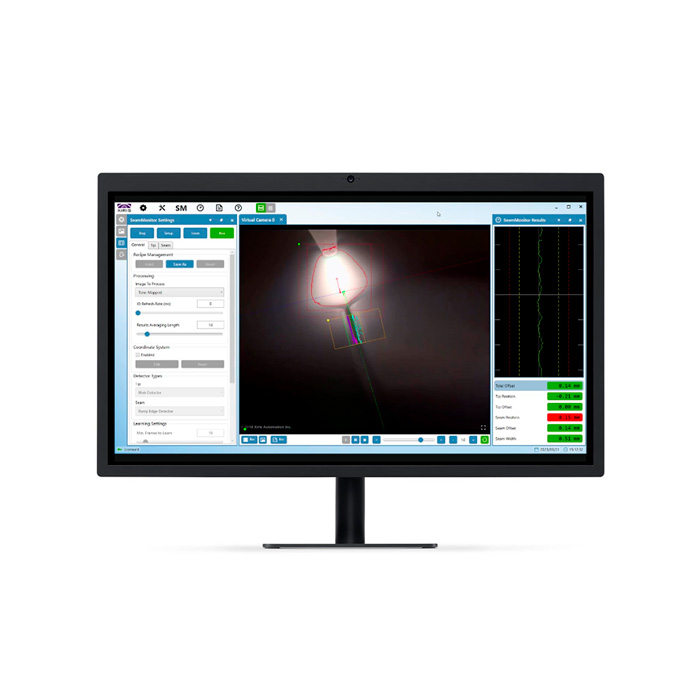

Welding Software

Record every weld, analyze trends, predict issues, and optimize continuously. Our software ecosystem builds a digital record of every weld, turning insight into action, and action into performance.

Weld Camera Tools

Our modular enhancement approach means you can scale your monitoring system with your operation, adding capabilities as your requirements evolve without major reinvestment.

As Featured in:

We searched many suppliers and decided on Xiris mainly because of the response time to our questions that we had and Technical support. The product has been in operation for one year without any failure. On their own they sent someone 2 months after installation for added training on features and maintenance. As a Seam Welder Manufacturer, support from our suppliers is Key.

Xiris has been a great partner for us. They have excellent technology, and their staff is highly committed and responsive to our needs and to any problems we have.

The scrap reduction due to instantaneous feedback makes this a cost-saving tool for our Tube Mill operators.

The system has been a very valuable asset to us … We appreciate and look forward to continued work with Xiris Automation.

I would highly recommend Xiris vision systems to anyone that wants a robustly built weld monitoring system that can be custom tailored to your specific needs.

The operators like using the system for its ease of use and instantaneous response to mill adjustments helping them produce consistent high quality tubing.

We’re thrilled with the Xiris cameras and the effect they’ve had on our welding accuracy.

Xiris staff provide unparalleled service, continually going out of their way to show they really care about their customers and their product.

We’re very impressed with the Xiris Weld Camera system!

Frequently asked questions

What is the real impact of weld monitoring systems on our production costs?

Use factual language such as “supports,” “helps improve,” “enables visibility,” “may assist with,” etc.

Industries that we serve

Applications of weld monitoring Systems

Do we need to retrain our operators or change our processes?

How does this integrate with our existing systems?

What makes you different from other weld monitoring providers?

How long does implementation of weld monitoring systems take without disrupting our production?

Can we start small and scale later?